Sustainable 3D Printing

for Future Ready Construction

Additive to Predictive Manufacturing for Multistorey Construction Using Learning by Printing and Networked Robotics

Eco-Friendly Materials

Develop and utilize 3D printing materials made from recycled construction waste and local resources, reducing design time by 50%.

Smart Building with AI

Implement AI-driven “Learning-by-Printing” methods to enhance construction precision and ensure high-quality builds.

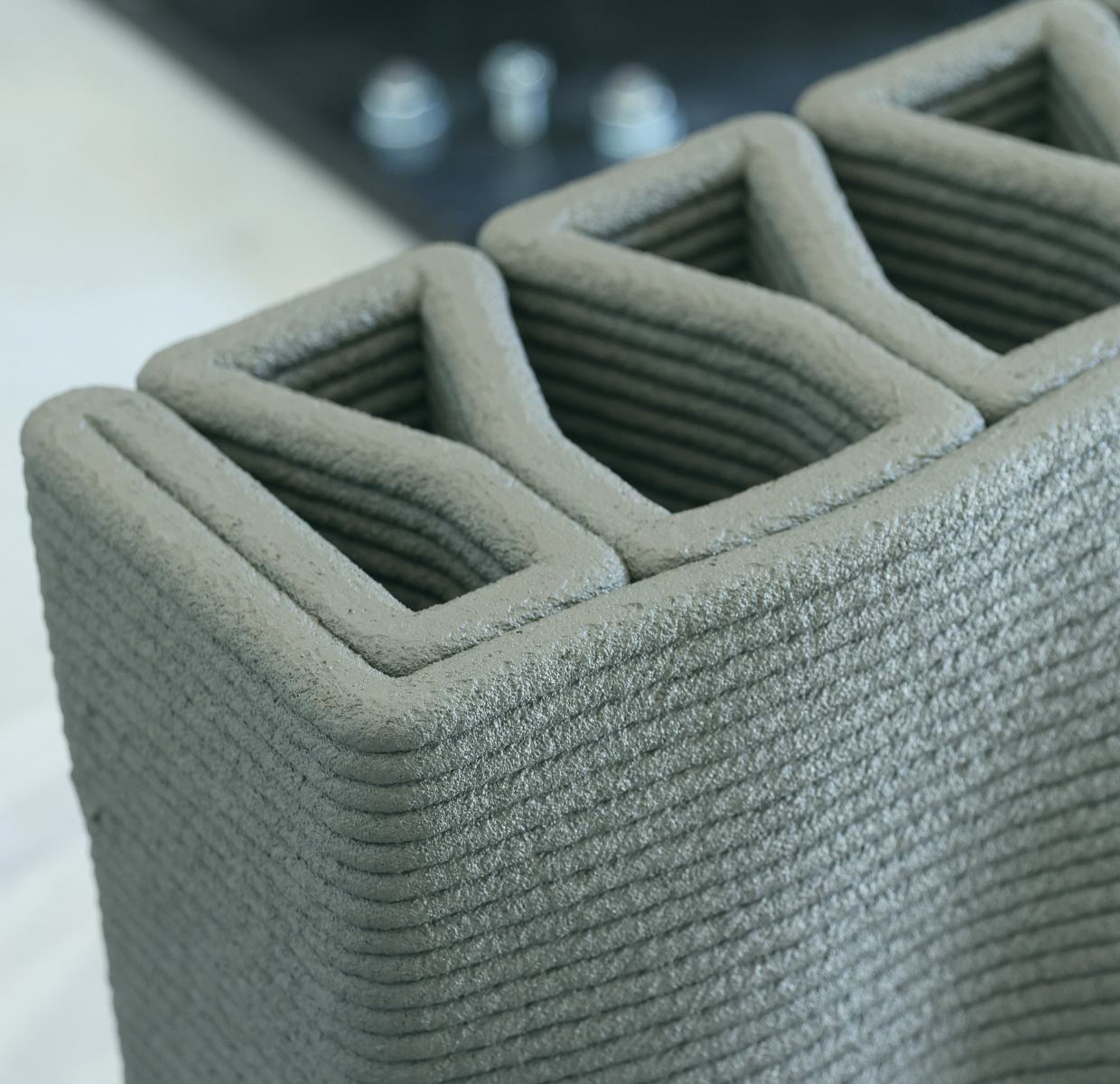

Efficient Structural Design

Create robust and sustainable structural components that cut material usage by 50% and lower carbon emissions.

Real-Time Site Planning

Use digital models to deliver real-time insights for planning and coordination, optimizing robotic construction workflows.

Eco-Friendly Materials

Develop and utilize 3D printing materials made from recycled construction waste and local resources, reducing design time by 50%.

Smart Building with AI

Implement AI-driven “Learning-by-Printing” methods to enhance construction precision and ensure high-quality builds.

Efficient Structural Design

Create robust and sustainable structural components that cut material usage by 50% and lower carbon emissions.

Real-Time Site Planning

Use digital models to deliver real-time insights for planning and coordination, optimizing robotic construction workflows.

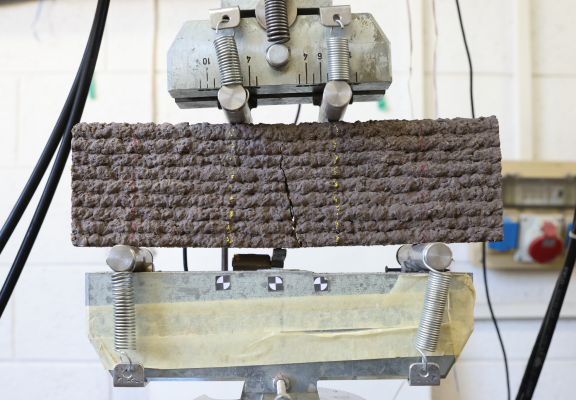

Testing the Strength of 3D-Printed Structures

To ensure the reliability and durability of 3D-printed components, rigorous mechanical testing is conducted on printed cementitious materials. These tests simulate real-world stress conditions to evaluate structural performance, including load-bearing capacity and material resilience. By optimizing material compositions and geometries through these experiments, AM2PM aims to achieve lightweight yet robust components that reduce material usage by 50% while maintaining or exceeding traditional construction standards. These advancements contribute to creating sustainable and high-performing structures for future construction projects.

Timeline of Key Achievements

We outline the major milestones that guide our journey. Each milestone represents a significant achievement in our mission to develop cutting-edge solutions for 3D construction printing, blending technological innovation with environmental sustainability. This roadmap demonstrates our progress and highlights the contributions of our project partners.

Completion of Characterization Protocol and Raw Mix Design

Development of standardized protocols for mix design with regular raw materials and their characterization.

March 2025 | Technion

Digital Twin Infrastructure

Creation of a computational framework to facilitate virtual modeling and predictive analysis of structural designs.

September 2025 | TU/e

Set of Compositions for Prototyping

Finalization of material compositions tailored for prototyping, ensuring robust and sustainable construction.

March 2026 | Technion

Optimized Parameterized Components

Development of fully optimized and parameterized components, enhancing adaptability for various use cases.

September 2026 | Technion

CPS Orchestration Architecture Framework

Specification and design of a cyber-physical system (CPS) architecture to seamlessly integrate all project components.

September 2026 | TU/e

First Optimized Structural Element Printed

Successful printing of the first optimized structural element, demonstrating practical applicability.

March 2027 | WASP SRL

AI Model for Predicting Printing Outcome

AI-powered model achieving 99% accuracy in predicting 3D printing outcomes under laboratory conditions.

September 2027 | TUM

Evaluation of the pilot performance of digital technologies in 3D printing.

Evaluation of the pilot performance of digital technologies in 3D printing.

September 2028 | WASP SRL

Life Cycle Assessment (LCA) Impact Assessment Complete

Comprehensive report on the environmental sustainability and life-cycle impact of 3D construction printing processes.

September 2028 | DTU

AM2PM is transforming construction with sustainable 3D printing and advanced digital technology.

Combining AI, automation, and digital twin systems to create eco-friendly, efficient building processes.