ABOUT

The Challenges of Construction Sector

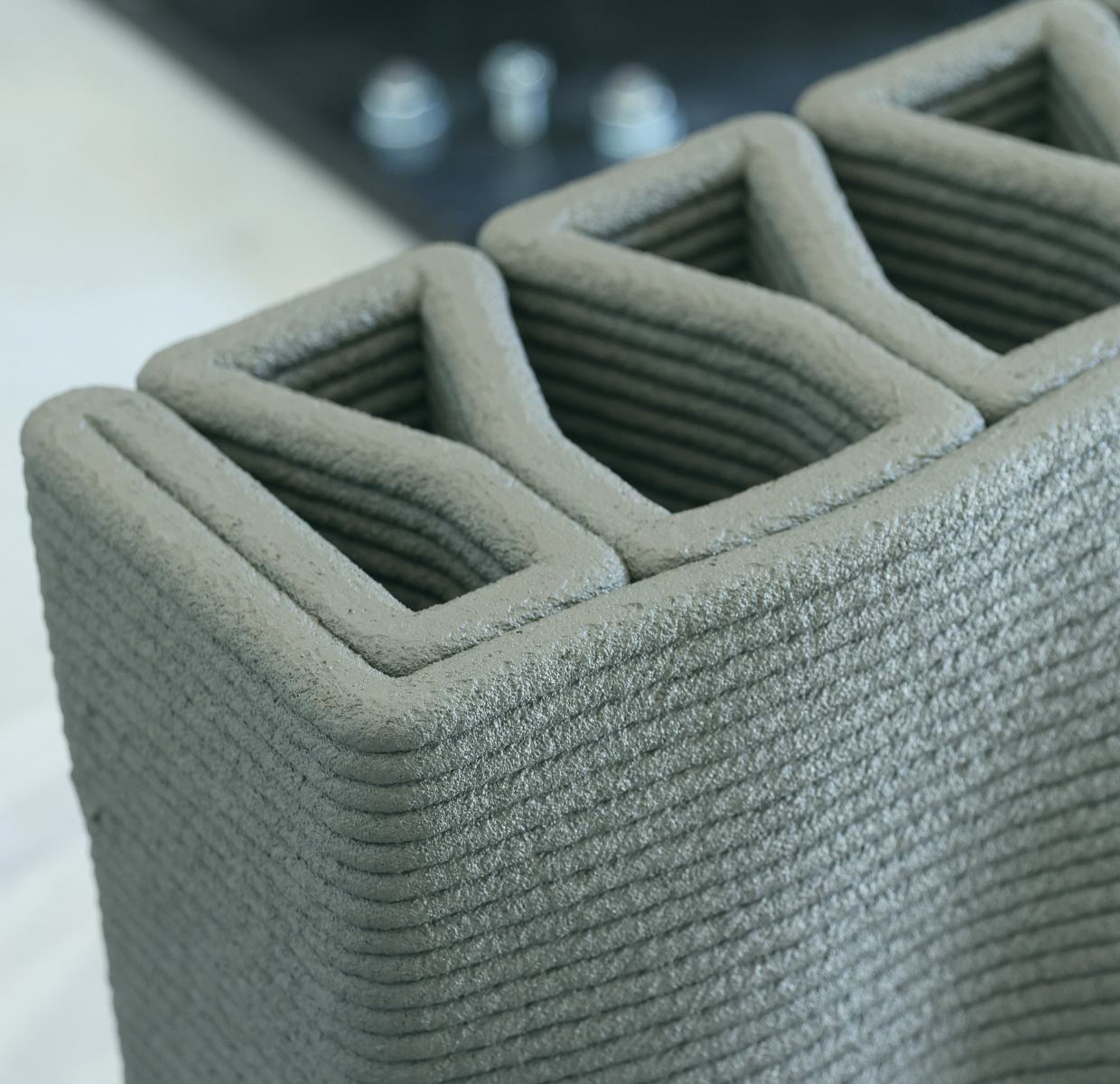

The construction sector is under pressure: climate change, housing shortages, rising costs, and a lack of skilled labour are all driving the need for smarter, more sustainable building methods. One of the most promising innovations is 3D concrete printing (3DCP), which can reduce waste, speed up construction, and enable complex architectural designs.

Despite its potential, 3DCP still faces key challenges:

Limited automation makes it hard to scale up for large buildings.

Lack of real-time monitoring during printing increases the risk of errors and material waste.

Production inefficiencies lead to high energy use and inconsistent quality.

Manual adjustments are still needed throughout the process.

Missing predictive tools prevent engineers from planning or optimising resources.

Disconnected systems between design, robotics, and construction slow down decision-making.

AM2PM tackles these challenges head-on, offering a unified framework that brings intelligence, efficiency, and sustainability to 3D concrete printing at scale.

Our Vision and Mission

AM2PM (Automation and Monitoring for Predictive Manufacturing) is on a mission to redesign construction using robotics, artificial intelligence (AI), and smart digital tools. Our goal is to create fully integrated digital system that merges automation, real-time monitoring, AI-driven decision-making, and sustainable material use.

This new approach will help:

Predict and prevent issues before they occur

Reduce environmental impact through smarter material use

Speed up construction, while improving safety and lowering costs

Rather than relying on disconnected tools or isolated upgrades, AM2PM brings all aspects of modern construction together under one intelligent framework.

As a European initiative, AM2PM supports key EU strategies like the Green Deal and New European Bauhaus. We aim to transform traditional construction sites into digitally connected, automated environments, enabling the efficient and sustainable construction of multi-storey buildings.

The impact? Up to 50% less material use, 29 million tons less embodied carbon, and over €11 billion in potential savings across Europe every year.

Our 6 Key Objectives

AM2PM focuses on six main goals that work together to tackle today’s challenges and build the construction sites of tomorrow:

Concept

AM2PM is revolutionising construction by merging 3D concrete printing, AI, robotics, and digital design into a single intelligent system. The goal: to make construction more efficient, sustainable, and data-driven.

At the core of the project is a Digital Twin platform that connects all stages of the construction process—from material development to real-time monitoring and on-site automation. This creates a cyber-physical construction system that addresses key industry challenges such as environmental impact, labour shortages, and the growing need for digitisation.

AM2PM focuses on three interconnected pillars:

Material synthesis using recycled and low-impact cementitious mixes

Structural optimisation with AI-guided, lightweight designs to reduce material use by up to 50%

Predictive AI platform that uses sensors and simulation to monitor, evaluate, and improve construction processes

Making a Real Impact on Construction

These innovations enable:

Smarter material choices for architects and designers

Real-time decision-making based on data

Safer, more efficient robotic construction sites

Reduced emissions and resource use

A “Living Lab” to test and validate solutions in real-world conditions

Our Research Method

Our approach follows an interative design process that continuously improves and adapts. The journey includes:

Problem Investigation - Understand what needs fixing and why.

Treatment Design - Develop ideas and technologies to solve those problems.

Treatment Validation - Test whether the solutions work.

Evaluation - Assess the results and feed

Our Research Method

Our approach follows an interative design process that continuously improves and adapts. The journey includes:

Problem Investigation - Understand what needs fixing and why.

Treatment Design - Develop ideas and technologies to solve those problems.

Treatment Validation - Test whether the solutions work.

Evaluation - Assess the results and feed them back into the design loop.

This cycle connects material science, AI tools, and structural design into one integrated method, helping us build smarter at every step.

Supported by leading universities, research institutions, and industry partners across Europe, AM2PM is turning advanced research into practical solutions for the future of construction. (Link to Consortium page)